Since the introduction of Steel “H-Finned” tubes in the 1950’s, this product has been widely adopted throughout the industry as it has the ideal heating surface for modern high pressure boiler economisers. The fact that our Steel “H-finned tubes” have around 9 times the heating surface of a plain tube of the same length and diameter, results in fewer tubes being required to achieve the same heat duty.

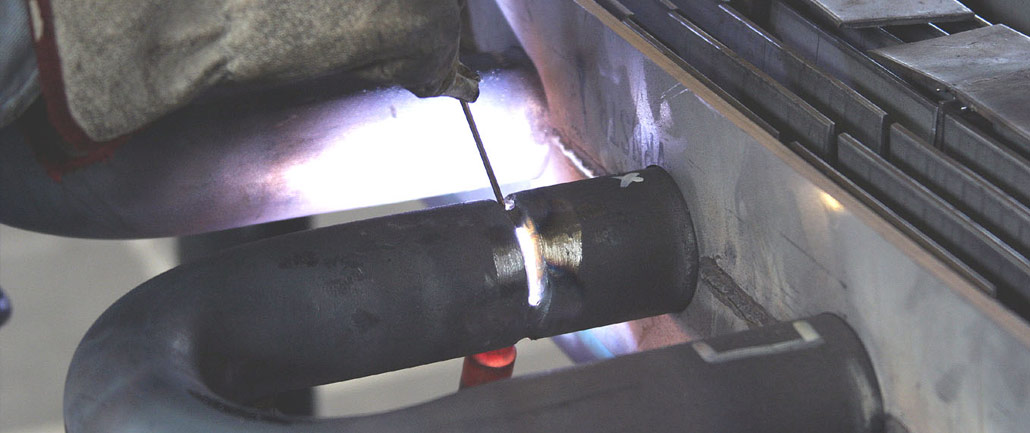

Pairs of shaped steel fins are fusion-welded to the single tube under carefully monitored conditions. Our custom designed fin welding machines ensure very precise indexing, fin pitch along the entire length of the tube, as well as accurate fin alignment and parallel fin attachment. We are one of very few global manufacturing companies with the capability to produce and supply this product to the Power generation Industry.

| Configurations |

| Tube O/D / Dia mm = 38mm to 63.5mm Tube length : up to and including 12000mm |

| Fin Thickness : 2mm to 4.5mm Fin Pitch : 8mm min Fin Shape : Rectangular of various Sizes |

| Base Tube material Typically carbon and low alloy Steels |

| Fin material Carbon Steel HR4 and equivalents |